IT'S GOING TO HAPPEN

by

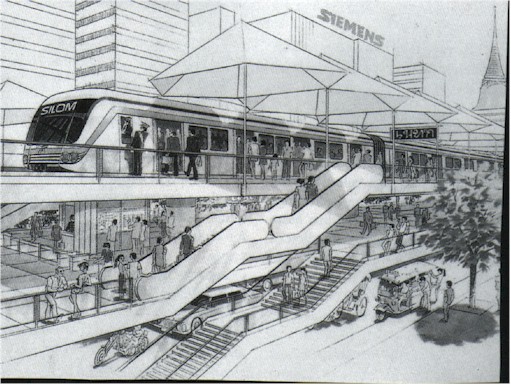

The Skytrain that is, and it's closer than you think. Scheduled launch is 5 Dec 99, the King's birthday next - less than a year away. Imagine, Bangkok with a mass transit system. And one of the key movers and shakers behind this project is Siemens.

Dieter Stingl is vice-president of Siemens Transportation Systems. The native of Kiel in Schleswig Holstein graduated from the University of Kiel where he studied electrical engineering.

He has been with Siemens for thirty-eight years now. Twenty- three of those years have been spent overseas, primarily in Asia, as he has worked in South Korea, China, Japan, Malaysia, Hong Kong, and now Thailand.

Stingl says Siemens initially became involved in mass transit systems for Bangkok with the Hopewell Project (which was put on hold for various reasons, and is still being fought over). This brought the company in touch with the Bangkok Mass Transit System Company Limited (BTSC) and its Skytrain project. "As we are a leader in turnkey systems, we naturally took up the challenge to get involved in the first mass transit system for Thailand," says Mr Stingl.

The BTSC is the first fully privately-owned and privately financed mass transit project in the world. The system is an electric railway designed and constructed to international standards. It will use updated versions of proven transit system installations currently in use in other cities, particularly in Singapore, Shanghai and Guangzhou.

The goal of the elevated train system is to obviously help relieve Bangkok's chronic traffic problems as well as to provide the citizens of Bangkok, and the tourists visiting the city, with a fast and more efficient means of transportation within the central business district.

Construction is being carried out by the consortium comprised of Siemens AG and its partner, Ital-Thai Development Public Company Limited. Siemens is in charge of supplying the electrical and mechanical services, include the rolling stock and signaling system. Siemens is also responsible for the entire project management and systems design. The company will also provide extensive training to the operating personnel and will take care of system maintenance during the first five years of operation. As the project only has two partners, Mr Stingl says it is much easier to control.

All stations and trackway will be on structures elevated above the medians of city streets. These streets run through the central business district of the city. All land required to complete the project has already been provided to the BTSC by the BMA.

The 64,000 sq.m. depot will be constructed at ground level at the northern end of the system. It will contain a full workshop and maintenance facilities and the main stabling area. It will also include an administration building and the control center from which the entire operation is monitored and controlled.

Stingl says the construction on the project is very well advanced (80% completed). The cars are manufactured at Siemens state-of-the-art facility in Austria, and then shipped to Laem Chabang from Bremerhaven, a northern port in Germany. As the cars are elevated people will be able to see them. The cars have been designed and developed in cooperation with BTSC. Porsche Design is responsible for the design of the cars. The seat alignment is curved in places, so that people will not feel forced to stare at someone sitting directly across from them.

Initial test runs have proven that the car is quiet and pollution free. Sanan Kachomprasart, the Minister of Interior was the Guest of Honor for the first test run.

There will be two lines: the first, the Sukhumvit Line stretches from Sukhumvit Soi 81 (Soi Onnut) and ends at the Morchit Bus Terminal. It passes along Sukhumvit Rd, Ploenchit Rd, Rama I Rd, Phayathai Rd, Victory Monument, and Phaholyothin Rd. The Suhkumvit Line is approximately seventeen km long and includes one common interchange station at Siam Square. The line has a structural provision for construction of one additional station in the future.

The Silom Line which starts at the foot of the Sathorn Bridge on the Bangkok side and ends east of Banthad Road near the National Stadium. From Sathorn Road it proceeds north to the junction of Klong Chong Nonsi where it turns east to Silom Road before running along Ratchadamri Rd and Rama I Rds. It is approximately 6.5 km in length with seven stations, including the shared interchange station. This line also has a structural provision for construction of one additional station in the future.

The system will stretch 23.5 km and will have the one common station at Siam Square. BTSC will have kiss n'ride facilities, as park n'ride facilities will not be available at the onset of the system.

"The system will run from 6AM to 12 midnight and it will have thirty-two three-car trainsets, with three spare trains. The signal system is designed for a ninety second headway and the system has been designed to increase its capacity by eventually using six-car configurations. One car can hold about 287 people in air-conditioned comfort, so a three-car train can carry approximately 861 (with a maximum 1106 crashload)," Stingl says.

"Initially, the Sukhumvit Line will carry 22,500 people an hour, in either direction, with three-car trains and a headway of 135 seconds. When we switch to six cars, it will carry 32,700 people an hour in either direction, with a headway of 180 seconds.

"The Silom Line will initially carry 13,500 people an hour in each direction, with three-car trains and a headway of 225 seconds. Later, when we switch to six-car trains we will transport 22,200 people an hour in either direction with a 270 second headway."

The trains will be powered by electric motors fed by an electrified third rail. The system will incorporate a signaling system that continually advises the train drivers of the optimum driving conditions including speed, braking, when to shut doors etc.

This automatic train control system will accelerate and decelerate the trains and will ensure that each train stops at individual stations according to schedule. Built-in automatic protection systems will ensure that no unsafe situation can arise. The train drivers will merely be required to ensure safe opening and closing of doors and to handle situations if they arise.

Each car will be approximately twenty-two meters long and three meters wide, with four doors to each side. Cars will be joined together by gangways which permit passengers to move freely from car to car. The car body will be constructed out of stainless steel. The three-car train wil have 126 seats.

The train platforms will be located on the upper level of the stations, about twelve meters about the road surface. The lower deck, or concourse level, will accommodate shops and ticket vending machines.

Each station will be about 150 meters long. With the exception of Central Station, all stations will be of the side platform type design, with two platforms located on the outer sides of the station and tracks running through the center. The Central Station will be of a center platform design with two platforms, one above the other. This permits the direct transfer of passengers between lines.

Commenting on the death of a taxi driver due to falling debris from the erection of the Skytrain, Mr Stingl says "Projects of this magnitude are bound to have accidents, and we deeply regret the loss of life. But the type of construction that you witness on this project probably wouldn't be allowed in most countries of the world due to the safety hazards involved. We are not allowed to block off areas during the daytime, and we can only block off certain sections at night. The whole process is very difficult, costly and time consuming.

"As for the safety of the cars themselves, Siemens has tested all the rolling stock at its own test center in Wildenrath which is near Dusseldorf and is the most modern in the world. It has subjected the cars to endurance trials, break tests and fire safety tests."

Fares will be Bt30. When asked if this wouldn't be too much for the average Thai, Mr Stingl reminds us that when traveling by bus people can sometimes take four different buses on one trip, where as the Skytrain might get you there in one trip with just one fare. Mr Stingl also says that in the future fares may be changed and gauged on distance traveled instead of having just one flat fee levied.

Parking is bound to be a problem for the stations at the end of the lines but Mr Stingl says the Bangkok Metropolitan Authority is trying to help solve that problem.

The total project costs are funded on a limited recourse basis by a combination of equity, Thai baht, and US dollar loans. Siam Commercial Bank is leading a syndicate of Thai financial institutions providing he Thai baht loans, Kreditanstalt fur Wiederaufbau (KfW), the German export credit bank, is arranging a syndicate of international lenders providing a large portion of the US dollar loans. The International Finance Corporation (IFC), the private sector of the arm of the World Bank, will also participate in the financing by extending a senior loan to the project.

COMPANY BACKGROUND

Siemens has been in business for 151 years now. Its first mass transit project was a train system in Berlin back in 1881. Its first underground project was in Budapest, Hungary in 1896. Since then it has provided transportation systems, equipment and services in over 120 cities around the world.

After entering into the field of communications technology with the introduction of the pointer telegraph, the company rapidly developed high-voltage technology spurred on by Werner von Siemens' discovery of the dynamo-electric principle. New application ideas were transformed into products and systems at a dizzying pace: the first electric railroad, the first electric street lighting, the first electric elevator, the first electric streetcar. Siemens became a pioneer in electrotechnology - a status it has never relinquished.

As a total systems provider, Siemens Transportation Systems integrates all areas of rail competence, from operational control systems to traction power supplies; from mass transit and mainline rolling stock to turnkey systems and services.

Over the last ten years Siemens has executed a large number of turnkey mass transit projects all over the world as a general contractor, consortium leader and project manager.

The company prides itself on completing its projects on time.

Siemens manufacturers complete systems which provide the best possible functioning of all components like rolling stock, signaling, control systems, power supply, communications, civil works, and many more. Even more important is the functioning of the interfaces between all components.

The company is also completely customer oriented. It can accommodate most any special wish, design, origin of make, or styling of rolling stock.

Siemens AC-Traction equipment was first built in 1978, and today there are more than 2000 of these systems in operation. Because of its high standard of quality, the Japanese have bought Siemens AC-Traction equipment for their Shinkansen train. This is the first time that non-Japanese equipment of this sort has been used on a Japanese train.

Siemens bogies (wheeled undercarriages) have a proven record, with more than 4,000 units in service worldwide. The Hong Kong MTR uses approximately 2,500 Siemens bogies, the Singapore MTR another 800, and systems in Shanghai, Guangzhou and Bangkok will all boast Siemens bogies.

Summing up, when people around the world think of electrotechnology and electronics, they naturally think of Siemens. The company is well-known for its ability to design and build complete systems and for providing unmatched technical service. Siemens is also the world's leading systems provider.

Of the 50 largest German industrial firms operating in 1913, only ten are still in existence today. And none of Siemens competitors from those days has survived into the present time. Today Siemens employs 400,000 people in 190 countries throughout the world.

Siemens has left its mark on virtually every area of electrotechnology development. It currently holds approximately 90,000 patents worldwide. Each year, the company spends DM 35 million on research and development alone. Innovation is indeed the key to the company's success and its very existence.

SIEMENS - YOUR PARTNER IN THAILAND

For almost a century, Siemens has maintained economic and technical links with Thailand. Local trading companies have been selling high-quality products and systems produced by Siemens in Germany in areas ranging from telecommunications to medical systems and from power generation to industrial equipment.

During the past six years, Siemens has taken decisive steps to become more firmly entrenched in Thailand. Joint-ventures were formed with the T.N. Group for marketing, sales and service of Siemens private communication systems and Siemens Nixdorf personal computers as well as for the development of software for the Thai market.

Siemens and Berli Jucker Corporation established a joint-venture responsible for a broad range of Siemens products and systems, including industrial automation and building systems, drives and standard products, power generation, transmission and distribution equipment as well as transportation systems.

Another joint-venture was formed with B.Grimm & Co. R.O.P. covering the areas of public communication networks, network systems, and medical systems.

In a move to consolidate the activities of Siemens in Thailand, the last two joint-ventures have now ben merged into one company under the name Siemens Ltd. By combining the engineering capabilities of both companies, Siemens Ltd has strengthened its position in order to provide even better and faster service to its clients in many diverse markets.

Osram, one of the world's leading lamp manufacturers and a wholly-owned Siemens subsidiary company, was established under the name Osram (Thailand) Co., Ltd.

Schmidt Scientific is the representative responsible for handling the sales activities for Siemens semiconductors and passive components in Thailand.

More than 1800 people are employed by the various joint-venture companies, engaged in manufacturing, engineering, sales and marketing, service and maintenance, attending to customer requirements and ensuring total customer satisfaction.

THE HOPEWELL PROJECT

* The Hopewell project was originally designed as a multi-deck mass transit system including elevated expressways and trains as well as frontage roads and property development along its routes (Siemens was to have supplied to electric trains to Hopewell for the project)

* The network was planned to stretch 60 km (38 mile) above Bangkok's existing railway network and it was initially to have been completed by the Asian Games, but less than twenty percent has been finished since the contract was signed in 1991.

* Delayed implementation drove the Thai government to scrap the contract with Hopewell and the Ministry of Transport and Communications (MCOT) is looking for ways to try and revive the project.

* Hopewell plans to sue the Thai government for Bt100 million for reneging on a concession awarded to the company for building the US$3.2 billion Bangkok Elevated Road & Train System (BERTS). It is estimated that the company sank US$600 million into the project before work was halted in July of 1997.

* The State Railway Of Thailand (SRT), in turn, has threatened to sue Hopewell for US$1.6 billion for failure to execute the project as scheduled.

* The Hopewell project was not the first mass transit system to bite the dust in Thailand. Canada's SNC-Lavalin and the Bangkok tollway project of Japan's Kumagai Gumi fell victim to political interference in the early 1990s.

HOW TO DO IT RIGHT

James Mclean of Reuters describes what went right with the BTS project: "On 3 Nov 1990, the same day as Hopewell signed its contract, then Bangkok Governor Chamlong Srimuang unveiled plans for Tanayong Land Plc's Bangkok Mass Transit System, an elevate rail project.

"The 45-billion-baht scheme, arching on single pillars along central Bangkok's main roads, is set to be the first mass transit project completed in the traffic choked city when it opens in late December of 1999.

"The 23.5 km (14.1 mile) project, which the company claims to be the largest privately financed urban transit project in the world, originally faced political problems to those that confronted Hopewell.

"But BTS's chief operating officer now is former Bangkok Metropolitan Administration deputy governor Karoon Chandrangsu who was closely involved with the project from its inception. `I have somehow used this past experience in solving so many difficulties,' Karoon told Reuters.

"A well-connected local partner to help construct your project will ease political and financial pressures. `You are looking for companies that have sufficient cash flows to overcome snags along the way to keep working and who won't crumble at the first delay,' said Philip Sheridan, construction analyst at Thaimex Finance & Securities.

"Germany's Bilfinger & Berger Bau AG has a long-standing joint-venture with local contractor Ch Karnchang Plc and has built most of Bangkok's expressway system. Two years ago, this joint-venture formed half of a four-way venture awarded a US$930 million contract to build the city's first subway line.

"`We are a joint-venture with a local partner and that is very important, Ch Karnchang is the second largest contractor in Thailand with a very good record," said Oku Oka, manager of fellow subway joint-venture partner Tokyu Construction.

"The clout of Thailand's largest contractor, Italian-Thai Development Plc has been an essential element to the BTS project development, executives said.

"The project is a key component in ITD's backlog and has brought about an eight percent stake in BTS over the course of the construction.

"`I don't think that anyone else could do such work. They way we formed the consortium strengthened their capability,' Karoon said.

"Successful project routing through populated areas, without heavy reliance on adjacent property development for revenues, helped attract financial backing, executives said.

"`(You need) selection of routing that would somehow guarantee a minimum ridership for the program and a proper selection of technology,' Karoon said.

"BTS's stand alone forecasts a 700,000-per-day ridership. The project has property ties such as a stop linking directly to Sukhumvit's Emporium shopping center, but will rely primarily on fare revenues.

"Analysts say Hopewell's income projections were over-reliant on property. As Bangkok's real-estate market turned sour, Hopewell's Chairman Gordon Wu had to constantly seek more concessions from the government to satisfy his backers.

"BTS's route goes through suitable bits of Bangkok, the densely populated parts. Hopewell was running through areas where no one would take a train and had an expressway running beside it most of the route," Sheridan said.

Finis